PLC Input Output Wiring! PLC Wiring With Source and Sink Mode!Delta Plc Wiring! SNTECHNICAL

• 8 input-status LEDs indicating valid input connections • Each input implements a user-programmable current limit of 2 mA to protect from over current, while limiting power consumption • Selectable debounce filters of 3ms implanted for each input ensuring valid input levels are latched into the shift register and output to the PLC host

PLC Digital Input and Output Modules Instrumentation Tools

PLC Input Module Block Diagram PLC Input Module Circuit Diagram. It is clear form the above figure that the input module is consist of two section one is power section while the other is logical section, which are electrically isolated from each other. When push button is closed 220V AC is applied to the bridge rectifier, through resisters R1.

PLC Hardware Components (Explained in Plain English) PLC Academy

by Doug Taylor on July 23, 2020 Why are there so many types of PLC inputs and outputs? Modern PLCs are adaptable devices. Since ladder logic can work with analog values as well as on-off devices (called discrete inputs and discrete outputs), PLCs have evolved from their relay rack roots into very configurable systems.

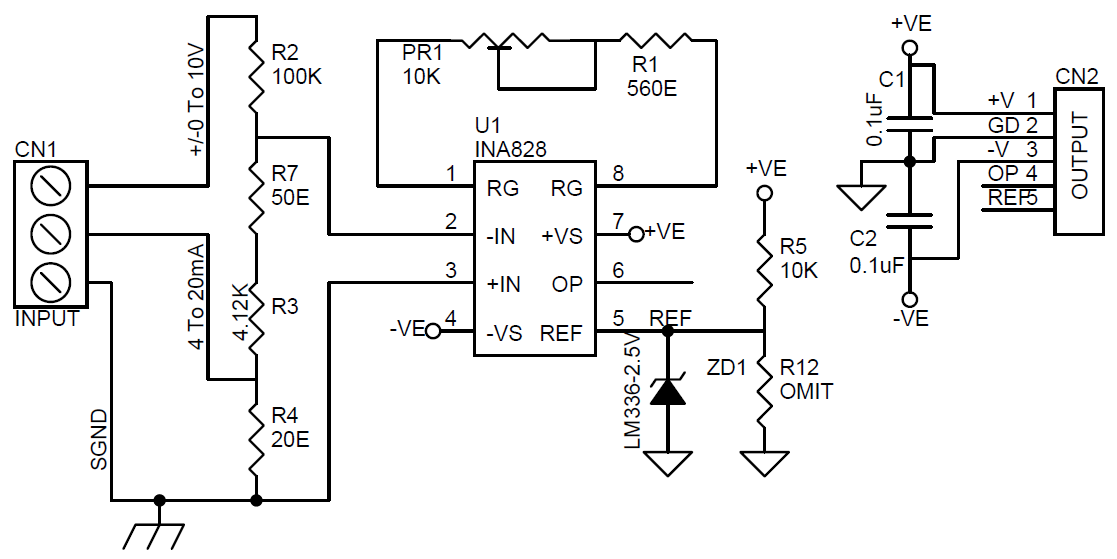

420mA / ±10V Analog Input Module for PLC

Discrete Input Modules A "discrete" data point is one with only two states on and off. Process switches, pushbutton switches, limit switches, and proximity switches are all examples of discrete sensing devices. In order for a PLC to be aware of a discrete sensor's state, it must receive a signal from the sensor through a discrete input channel.

Making Multi Way Switches using PLC Switch Control PLC Logic

Common PLC Input Devices In most PLC applications, there are a number of components that you will usually see. To name a few, there are push buttons, selector switch, and limit switches. Push buttons PLC Basics: Push buttons (Photo from Siemens) Push buttons are the ones that you will usually see as START or STOP buttons in a PLC control system.

What are the Features of PLC Inputs and Outputs The Engineering Knowledge

In a PLC system there will usually be dedicated modules for inputs and dedicated modules for outputs. An input module detects the status of input signals such as push-buttons, switches, temperature sensors, etc.. An output module controls devices such as relays, motor starters, lights, etc. Discrete I/O

Plc Input Wiring Diagram

An analog input converts a voltage or current level into a digital value that can be stored and processed in the PLC. They use words to determine the signal coming from the device. Example: 4 - 20 mA current Input - 8-bit resolution. 4 mA = 00000000 base 2 = 00 base 16. 20 mA = 11111111 base 2 = FF base 16.

Electronics Blog PLC Input Circuit for PSoC, Raspberry Pi, Beagle, OLinuXino, Cubieboard High

Optocoupler Input Circuits for PLCs by Lewis Loflin Here I'll introduce programmable logic controller (PLC) input circuits using opto-couplers. We use these devices to interface high voltage sensors to low voltage microcontroller logic and to isolate sensitive circuits from noise. I'll also discuss the concepts of SOURCE and SINK.

PLC Automatic Control of Two Outputs with one Input PLC Examples

A DI is a circuit designed to receive a binary signal transmitted from an industrial sensor and translate that input into a reliable logic signal for a PLC or industrial controller. Common examples of industrial binary signals are pushbuttons and/or temperature or proximity threshold indicators.

PLC Inputs What They Are, Different Types And Much More Engineer Fix

1. 24V Digital Input Module for PLCs and IEC 61131-2. In a PLC, the Digital Input Module is used to receive external 24V digital inputs from sensors or switches and transmit signals to the host controller. Fig. 1 shows the basic configuration of the 24V Digital Input Module.

eBook Automating Manufacturing Systems; with PLCs

Digital Input Modules Digital Input (DI) modules are used in Programmable Logic Controllers (PLCs) and Motor Drives to receive 24-V digital inputs from field sensors and switches. Isolation is used to manage ground potential differences. The input signal is interpreted as a logic high or low using a voltage comparator with hysteresis.

Plc Input Circuit Diagram Circuit Diagram

In this video, we learn about PLC input and output modules in the programmable logic controller. Hardware Parts and components in PLC.Get PLC tutorials here:.

Plc inputs and outputs explained in detail The Automization

A PLC has many "input" terminals, through which it interprets "high" and "low" logical states from sensors and switches. It also has many output terminals, through which it outputs "high" and "low" signals to power lights, solenoids, contactors, small motors, and other devices lending themselves to on/off control.

One Function of a Plc Input Interface Module Is to GracehasWiggins

What is the Input and Output Module in PLC? Multiple inputs (I) and output (O) modules are used in the PLC system. They provide an interface between the central processing unit (CPU) and programmable devices. What is Input Module? The module which interacts with the input signal is called as Input Module.

PLC Wiring Diagrams PLC Digital Signals Wiring Techniques

PLC controller output. the most commonly used devices are motors, solenoids, relays, indicators, sound signaling and the like. When starting a motor or a relay, the PLC can manage or control a simple system such as the system to classify products into complex systems such as the service system to position the head of the CNC machine.

All About PLC Analog Input and Output Programming

PLC inputs can refer to two different things, the first is an external device that is used to give information to the PLC. We also refer to PLC inputs as a physical part of the PLC where terminations are made (I1, I2, I3, etc).