How to clean, stain & seal a deck

Cleaning And Caring For Sealed Live Edge Wood. Use a soft, lint-free cloth or a microfiber cloth to dust the surface regularly. For deeper cleaning, mix mild dish soap with warm water and dampen a soft cloth with the solution. Gently wipe the surface, ensuring not to saturate the wood.

Wood Table Bases, Wooden Tables, Farm Tables, Home Decor Furniture

Carnuba Wax. Carnuba wax can be applied directly to unfinished wood as a protective sealer coat, and it will block moisture and serve as a barrier coat for spills of short duration. Carnuba wax is more effective when used as a furniture polish in combination with a shellac finish or other thin varnishes. The wax is usually rubbed onto the table.

How Much Weight Can A Wood Table hold? (A to Z) WoodWorkly

Instructions. Starting with clean table apply one coat of General Finishes Flat Topcoat in a thin layer. Apply top coat on with 2" paint brush in same direction as the grain of wood table. Let top coat completely dry 1-2 hours. Sand wood table with 220 - extra fine sanding block or sand paper.

I need advice on how to finish and seal the wood on the table I built

Avoid using water on unsealed wood, because it can alter the wood's grain and create roughness. 3. Stain the wood to change the color or to highlight the grain, if desired. Apply the stain before you apply your sealant so that it is able to soak into the surface.

Buy VASAGLE Nesting Side Table, Round End Table, Set of 2, Scandinavian

We've all been there. The wood is sanded down to a gorgeous, light shade. You apply one coat of sealant, and BAM, it's now dark brown. In this video, I try a.

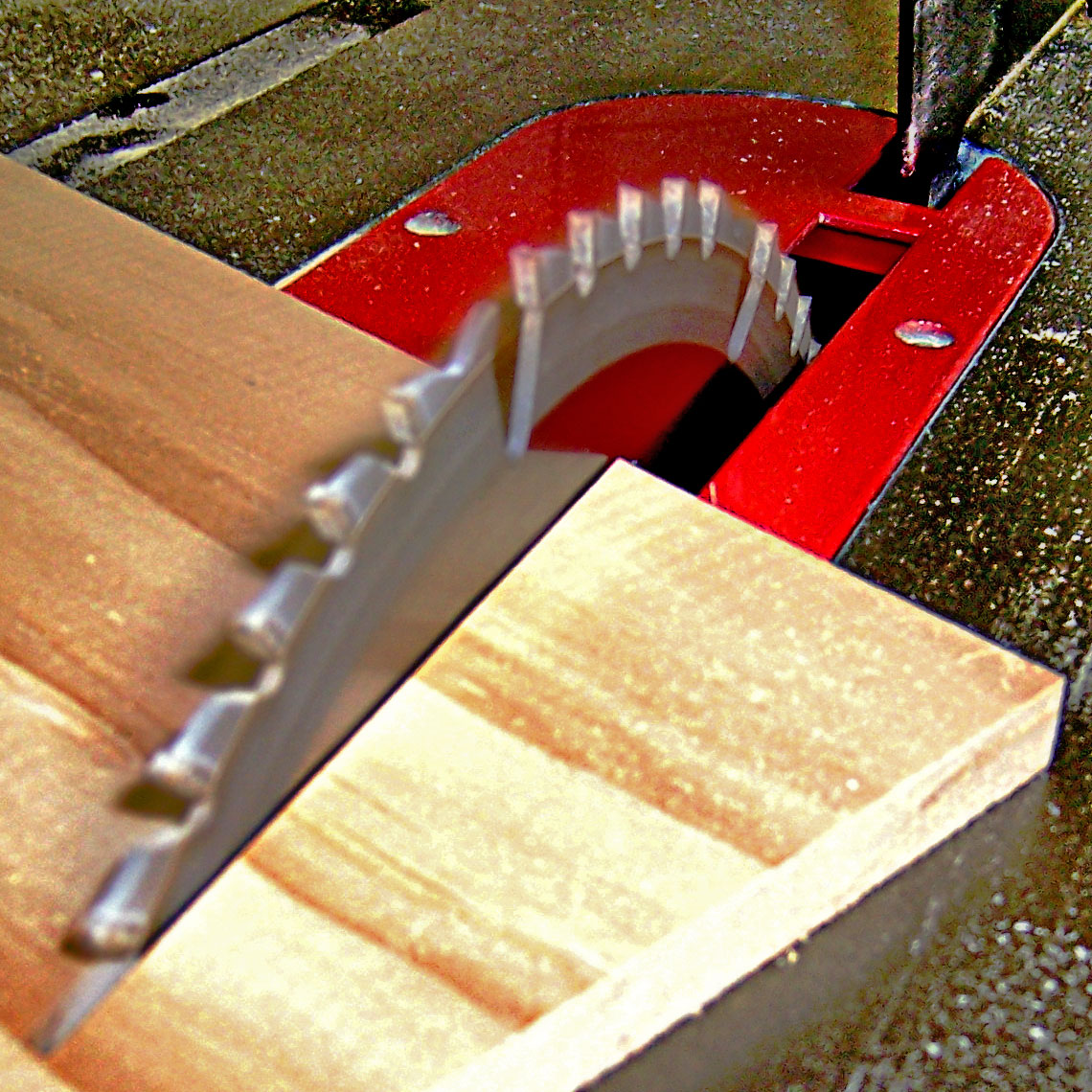

FileTable saw cutting wood at an angle, by BarelyFitz.jpg Wikipedia

Let the solution seep into the wood grain for 10 to 15 minutes before wiping away any excess with a clean cloth. Apply stain, paint, or sealer to the surface of your table with a foam brush to protect it and completely freshen its appearance. When staining wood, use slow, even strokes to get a uniform finish.

How to seal stained wood everything you need to know!

Apply a coat of stain-sealant to the thoroughly cleaned and sanded wood surface with a brush, roller, and/or paint sprayer. Allow the wood to fully dry and cure according to the product label.

Mingle Table Legs / Wood Table Ferm Living

Sealing a Wood Tabletop Using Lacquer. Formula Lacquer is a glossy material gotten from a mixture of tree resin dissolved in alcohol. Lacquer is one of the essential sealants for coating or sealing wood furniture. Many woodworking experts and professionals consider lacquer as the best sealant because of its unique properties.

bunch of dollars on oak wood table Stock Photo Alamy

Over the past several years I've been asked time and time again whether I did something to seal and protect the Restoration Hardware and Pottery Barn wood tables in our kitchen. The answer is "yes" and the way that I chose to seal them is actually something I spent a lot of time researching and experimenting with before figuring out the.

Home & Living Two tier wood table Coffee & End Tables

After I made sure the table was completely clean, I applied the first coat of General Finishes. Using a 2″ paint brush I applied a thin layer of the sealer in the same direction of the wood grain. It will look a little milky when you start apply the topcoat. Just be sure to apply the polyurethane evenly and that milky color will fade away as.

Sealing Wood Sealing wood, Wood cookies, Wood slices wedding

Tabletop sealing is a process involving sanding, spraying, brushing or wiping a specific product on the table to protect it. You don't need to use products such as sanding sealer, it's an unnecessary step. All products seal because they close pores in the wood. Skip the sealer and use lacquer to seal a tabletop for the best results.

Spring VO Peter Wood

For longer-term care, sealing a wood table allows you to wipe away dust, fluids, and other potentially damaging substances much more easily. There are a variety of popular methods for sealing your wooden table, however, and the frequency of application varies. Apply a natural oil finish. There are three major brands that we use at Makers Woodshop.

Andrianna Shamaris Couture Round Butterfly Teak Wood Inlay Table at 1stDibs

Step 3: Clean the Table. After sanding the wood table, the next vital step in the sealing process is to thoroughly clean the surface to remove any residual dust, dirt, or contaminants. This meticulous cleaning stage ensures that the sealant adheres effectively and that the final finish is flawless and long-lasting.

Wood White Table 3D Model • iMeshh

Let dry for 1-2 hours. You will know if the top coat is dry if it forms a powder when lightly sanded with a fine-grade (220-320) foam sanding pad or 400-grit sandpaper. Certain conditions such as humidity levels, temperature, etc. can affect dry time. If in doubt, wait longer.

black and white Spoon on a wood table Stock Photo Alamy

Another popular wood table sealer is rubbing oil. Oil does an incredible job of sealing wood surfaces thanks to the way it interacts with wood fibers. Unlike wax finishes that simply sit on the surface of your table, oil actually seeps into the wood's pores, revitalizing your wood's fibers and sealing the surface from the immediate atmosphere.

DIY Sealing wooden countertops YouTube

Here's a guide to help you seal your natural wood furniture at home. Step 1: Choose the Right Sealant. Start by selecting the appropriate sealant for your wood. Polyurethane is a popular choice for its robustness perfect for dark woods, while polycrylic works well for lighter woods. If you prefer a softer look, you can opt for wax finishes on.