Split Face Block Archives Elliott Block Company

Splitface Concrete Blocks have a deep textured relief which gives depth to the block unit while also exposing the inner aggregates. This lends itself to customization through the use of different colored aggregates. Both structural an non-structural Splitface concrete block units are available. Splitface concrete blocks are available a variety.

Split Face Blocks Lovell Construction Group, LLC San Antonio Concrete

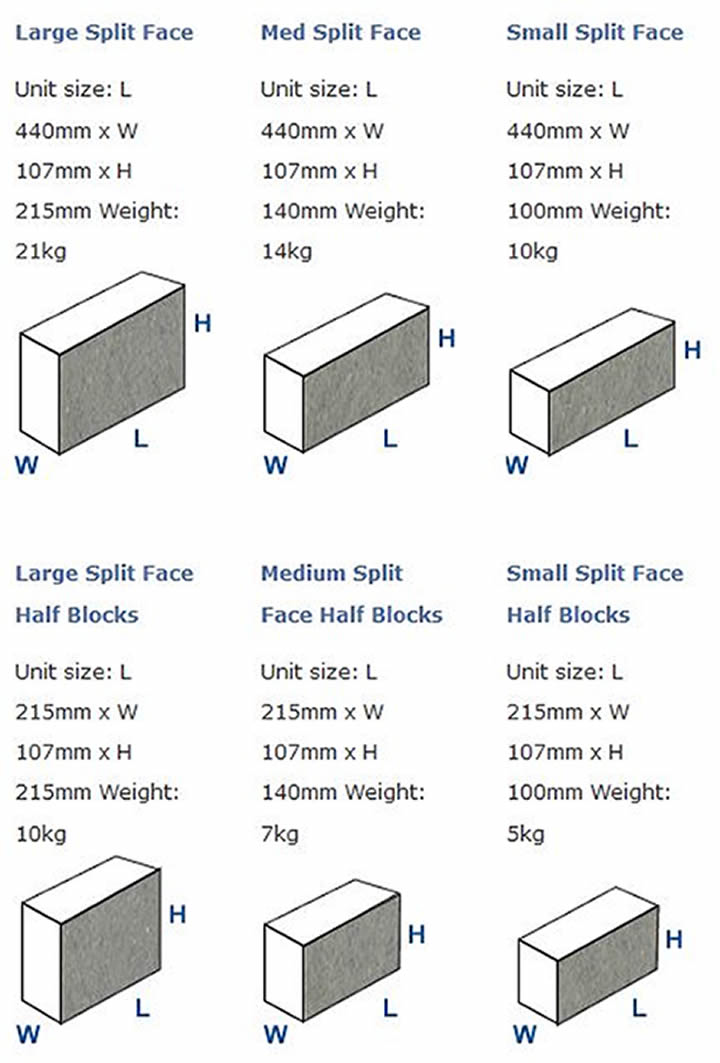

Split face textured blocks or rock faced blocks are manufactured using local natural aggregates that produce a very attractive light grey and buff colour. These split faced textured blocks are available in 3 different sizes. Corner Blocks (Quoins) are also produced to compliment this range. Mona Precast have split faced textured blocks in 3.

Split Face Block Wall Cost Architectural Masonry Series Firth

This measures in at more than 15 Mpa, despite the blocks weighing less than 10.5kg when dry. Available in a diverse range of colours, 200mm Series Split Face Block can be finished off beautifully with your choice of 3 styles of caps; The standard Coloured Smooth Cap, Tasman Full Cap or Tasman Half Cap. Each providing their own unique look.

8" x 8" x 16" Standard Split Face Block 1Side Grey Elliott Block

This 12" wide x 8" high x 16" long Split Face Solid Concrete Masonry Unit (CMU) is used in non-load-bearing and load-bearing walls and structures to provide an insulated, long-lasting structure resistant to fire, moisture, and pest. The rough surface of the block provides an attractive and natural-looking finish, eliminating the need to cover the block with veneer material and reducing.

Splitface Concrete Blocks RCP Block & Brick

Split face. Cost-effective and offering flexibility, Splitface adds a prestigious appearance to any building, whether creating complete, imposing structures or in combination with other Ibstock products, in feature panels and bands. Affordable elegance for any building.

Foundation split face MasonryBlockworkLayersLabors YouTube

Split Face blocks are a highly flexible product that suits residential and commercial buildings, and landscape retaining walls. Whether internal or external, load bearing or non loadbearing Split Face blocks of different sizes from 90mm to 190m are available. Retaining wall Split Face blocks are also available with cut-outs for horizontal.

Sealing Split Face Block Doesn't Work Ask Nagel Realty

As described earlier, split face block and concrete blocks are highly porous. Most importantly, applying the proper water repellents to the exterior block such as silicones, silanes, siloxanes, or elastomeric coating, can waterproof the block's facade assembly is the most important. The concrete or cement block wall should be power-washed.

Pin on Wall Detail

The material is manufactured using aggregate, Portland cement and course sand. During manufacture, a complete 16″ block is "split" in two so as form two 8″ thick blocks, each with a rough face along the split edge. The finished product resembles rock-faced masonry in Richardsonian Romanesque houses popular in the mid-1880s (below).

Decided to use a split face block Build my own house, Log homes

From sensitive Mid-Century Modern projects to contemporary Australian builds and beyond, the Vertico Block fits seamlessly across a vast array of architectural styles and is indicative of GB Masonry's pioneering craft and ongoing innovation harnessed, as always, from unwavering imagination and a passion for perfection.

split face cinder block wall Split Face Cinder block walls, Block

Architectural Masonry. Architectural masonry is a decorative-faced concrete masonry block with design quality and dimensional accuracy. A flexible material that provides the benefits of a structural product, along with a large range of textures and finishes that utilise a multitude of aggregates and pigments to suit a variety of designs.

split face block Google Search Masonry blocks, Masonry, Concrete blocks

Blocks. 100 Series Splitface. These 100mm wide splitface concrete blocks are available in Grey or Parchment and combine strength, durability, and ease of construction and provide highly cost effective solutions for everyday construction applications. Other colour options are available as special orders upon request.

Decorative Cmu Veneer Shelly Lighting

Split Face. Split Face Block provides an attractive alternative to standard precision block. A broken rock-face appearance with a rough and rugged texture reveals the beauty of the natural aggregates used in the block's manufacture. This unique texture allows a ballet of sunlight and shadow to dance across the building's facade throughout.

Split Face Blocks Lovell Construction Group, LLC San Antonio Concrete

The rustic finish of split face creates a distinctive look. The splitting process used to create these blocks produces a bold textured, exposed aggregate finish. Alabaster Architec Honed 10.01 Full 390x90x190 . Available in: VIC, NNSW, SNSW . POA. Embrace the elegance of this block as its subtle sparkle of natural aggregate shines through..

Barry & Tim on Instagram “split face blocks on a townhouse

Split face masonry is thermally efficient, sound absorbent, and fire resistant- making it a preferred product in the construction of commercial projects such as theaters, schools, and municipal buildings. It is manufactured as a normal-weight or lightweight unit; it conforms to ASTM C 90 standard specification for load-bearing concrete.

Split Faced Textured Blocks, Rock Face Blocks

Concrete Blocks have a smooth face and are most often buried in walls right behind the exterior brick or stone as an inexpensive way to add stability and depth to a masonry wall. Split-Face Blocks have a rough texture, which makes for a more aesthetically pleasing look on large exterior walls (like what you find on the side and rear walls of.

8" x 4" x 16" Split Face Block 1Side Cap Tan Elliott Block Company

The use of blockwork allows structures to be built in the traditional masonry style with layers (or courses). such factory-produced units are called "split-rib" or "split-face" blocks. Blocks may be scored by grooves the width of a mortar joint to simulate different block modules. For example, an 8-by-16-inch (200 mm × 410 mm) block may be.