What weave pattern you like most? Diy welding, Welding, Welding and

Weaving is a technique used to control the amount of heat being conducted during the process. You can either push or pull the welder. Pushing the welder towards the joint is the most common option and the easiest for beginners to learn. It is also called the forehand method. It gives you a shallow penetration.

Welding Techniques

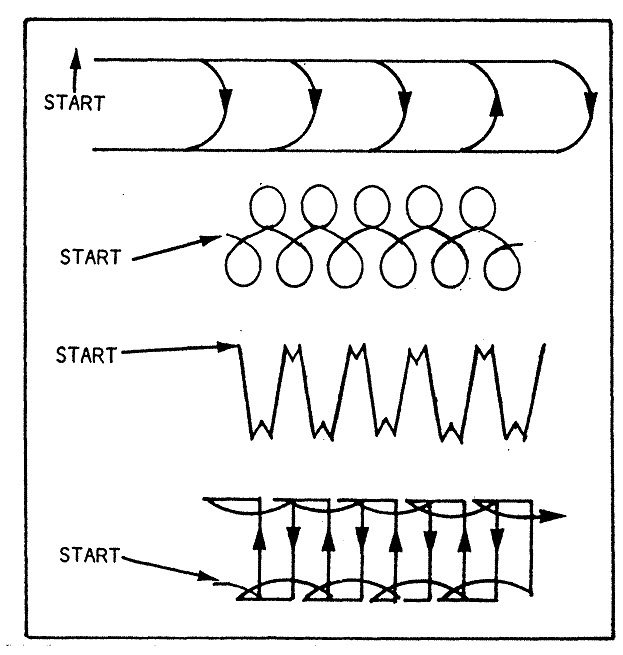

Weaving is a side-to-side motion of the welding arc during transferring material to the joint to be welded. Weaving allows filling the joint by moving the arc. Giving side-to-side motion for welding means moving the material in the joint to be welded.

148 best images about Welding art on Pinterest Instagram, The cup and

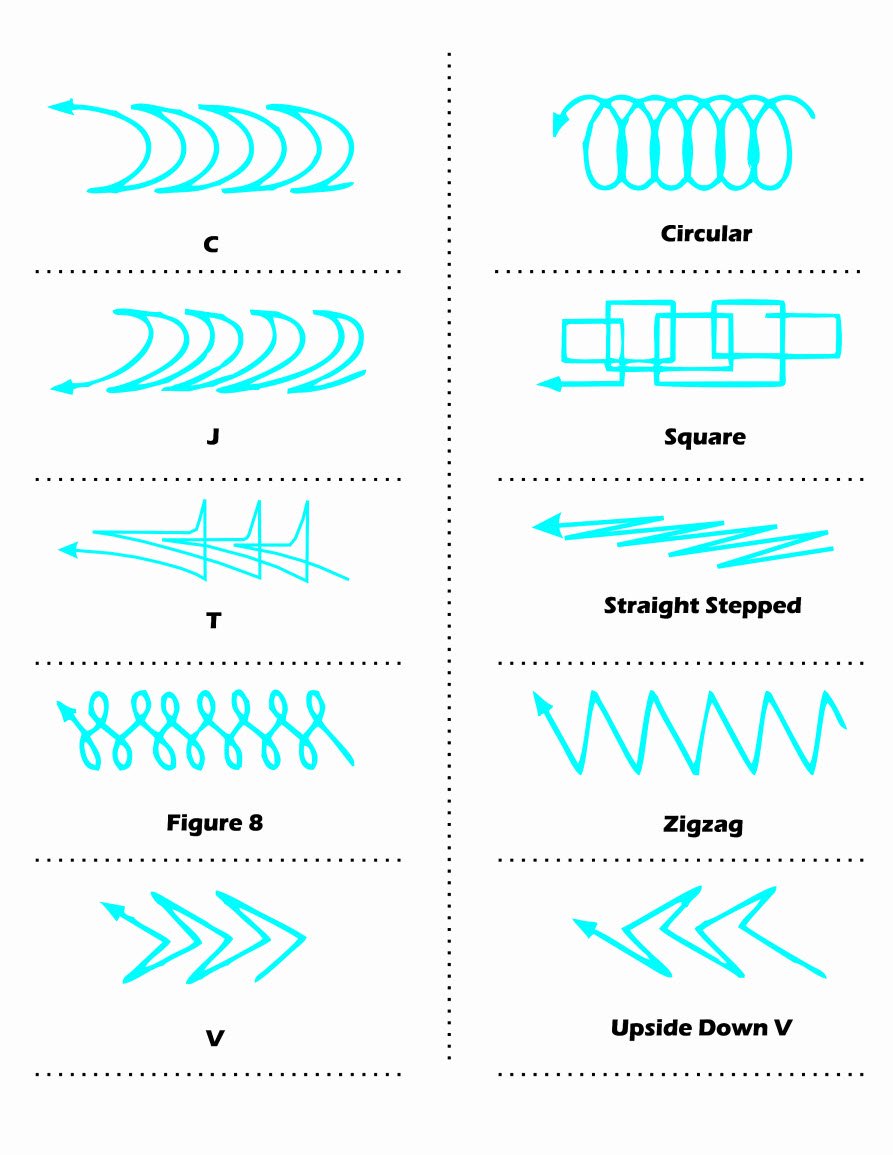

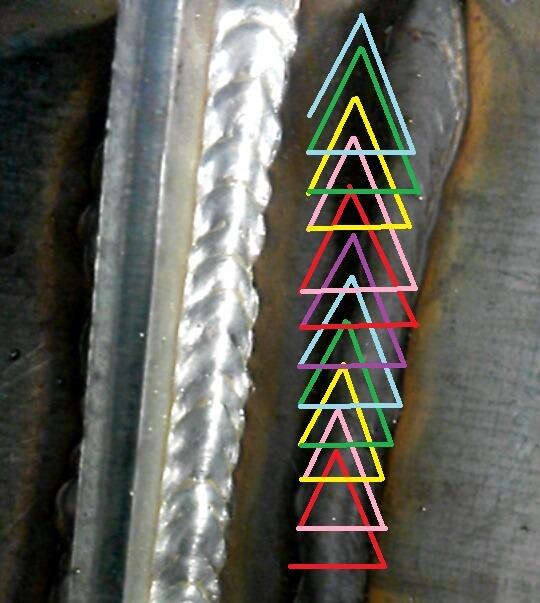

7 Jagged weave bead 8 Factors on which welding bead patterns depend on 8.1 Voltage and wire feed speed 8.2 Travel speed 8.3 Welding angle 8.4 Shielding gas 8.5 Metal type and thickness 8.6 Welding method 9 FAQ 9.1 Should you weave when MIG welding? 9.2 What is the 5 weaving motion in welding? 10 Conclusion What are welding beads?

Welding Techniques

Welding weave patterns are used to control the weld's width and penetration, making them essential for achieving high-quality welds in various applications. a. Stringer Beads

DIFFERENT TYPES OF WEAVING USED IN THE PROCESS OF WELDING Nikit

Weave patterns in MIG welding refer to the intentional side-to-side movement of the welding torch during the welding process. These patterns significantly impact the final weld bead's shape, size, and penetration depth. Properly executed weave patterns ensure uniform heat distribution, prevent overheating and enhance the weld's structural.

Weaving in welding A comprehensive guide to weave patterns

Weave Bead Welding! Weave bead welding is exactly as it sounds; you will make a weaving pattern in order to cover a larger area. You use this motion to make cover welds over stringer beads (multipass welding). In other words you use this when you are layering welds. It's used when you make two or more welds on the same seam.

Weld by Aluminum_expressions on Instagram westcoweld ukwelding

Practice Weave Welding Patterns while safely learning about an Electrical Circuit. Part of the Welding Basics curriculum by Paxton/Patterson College & Career.

basic weave bead patterns Schweißprojekte, Schweißen, Metall schweißen

The weld pattern is the way you move the welding gun along the joint, creating a series of overlapping beads that form the weld. The weld pattern can influence the penetration, appearance, speed, and distortion of your weld.

Welding Techniques

Weave bead welding is exactly as it sounds; you will make a weaving pattern in order to cover a larger area. You use this motion to make cover welds over str.

Tig weave Ремесло художественной сварки, Проекты по художественной

There are basically two ways to weave a TIG weld: walking the cup and freehand. We'll hit on the latter in a bit, but right now let's focus on the former. Most people assume that all weaved TIG welds are "walked." It's by far the more popular method, and for good reason.

Weld by toolndiewelder westcoweld ukwelding welding tigweld tig

A steady motion welding pattern consists of moving your welder back and forth at a steady pace. Advantages A major advantage of the steady motion welding pattern is its simplicity. You have to go back and forth, with no complicated maneuvers necessary. It is also very versatile. When in doubt, you can use this pattern for any situation.

Welding Beads What Are They? & Different Types

Weaving Welding Technique Pattern . Weaves are used for wider welds and range from a tight side to side motion that can be a stringer bead to welds that are wide and big for a single pass. Weaves are good for big joints that have no distortion issues. Just as a note in most shipyards weaving is not allowed. There is a formula that allows so.

Welding the Way — There are several types of bead weave patterns...

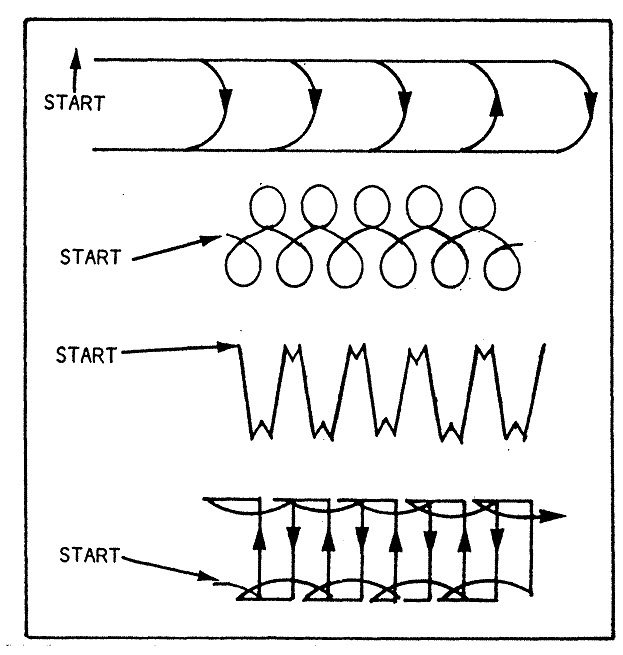

Weave techniques Patterns There are several different weave techniques and patterns that can be used in welding, each with their own advantages and disadvantages. Some common weave patterns include: V-type: This technique involves moving the torch or gun in a V-shape pattern along the joint.

Tig weave Welding Goggles, Pipe Welding, Welding Rigs, Arc Welding

Weave bead welding involves making a weaving pattern in order to cover a larger surface area. This motion allows you to make cover welds over stringer beads, otherwise known as multipass.

"The art of Welding" weavewednesday tig weldporn weldlicious

This pattern deposits more weld metal than the "V" and creates a better-looking bead. A short stickout of no more than 3/8″ is also important for deep penetration. Upside-down V for vertical-up welding Triangle weave for vertical-up welding . Short-arc can also cause fusion problems when welding downhill. That happens because the fast.

Weaving in welding A comprehensive guide to weave patterns

The six common MIG welding patterns we'll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and J pattern. All patterns have pros and cons, difficulty levels, and the best situations to use them.